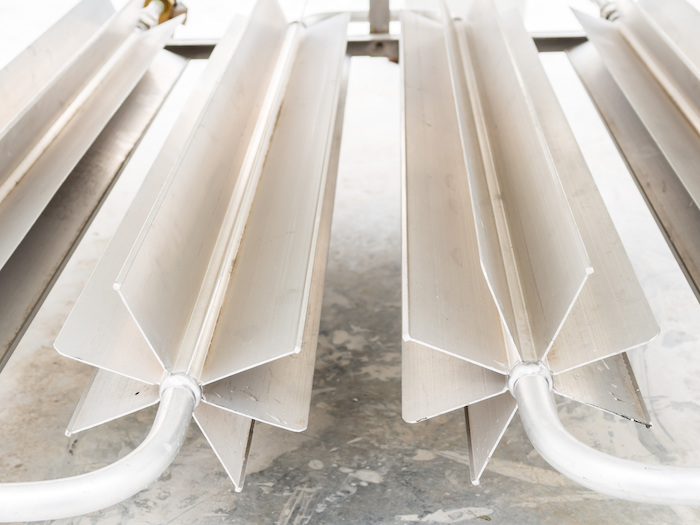

CO-Drive Energy Capture

CO-Drive captures lost energy when liquid gases are evaporated as part of brewing, food preparation or healthcare requirements.

CO-Drive can be installed where liquid gases are either used in or form part of a production process. For example: Carbon dioxide in brewing and soft drink production (carbonisation), nitrogen in food preparation and oxygen in the healthcare sector (hospitals).

CO-Drive captures the lost energy and is able to re-distribute it to other areas; air-conditioning in healthcare and chiller equipment in food and drink production.

Power savings, reduction in carbon dioxide emissions and increases in productivity can all be realised through a CO-Drive installation.

learn moreadvantages of CO-Drive

Saves Energy

CO-Drive can significantly reduce the power requirements within key areas of production or operations. In some cases, >50% reduction has been achieved !

learn more

Go Green

By reducing the amount of power required, there is a significant reduction in the amount of greenhouse gases produced (carbon dioxide and sulpher dioxide).

learn more

Improve Productivity

The efficiencies that CO-Drive brings means there is less load on critical high value components. Greater capacity without further investment and extending the operational life.

learn more

No Risk

CO-Drive is a retro fit solution and never comes into contact with the product itself. All existing management controls are unaffected.

learn more

Discuss how CO-Drive can be added into your production process Contact us